In 2000 iso 14644 2 was published which began the process of fed std 209e being canceled.

Clean room definition iso 14644.

Cleanrooms are classified according to the cleanliness level of the air inside them.

So for example an iso class 5 cleanroom has at most 105 100 000 particles per m.

Positive pressure keeps new particles from entering the clean area.

Air distribution during which primary air entering the cleanroom or clean area is mixed with the room air by means of induction iso 14644 1 2016 06 the filtered clean air is introduced into the clean room with a swirling effect and generates an increasing dilution of the particle concentration.

This part of iso 14644 specifies the classification of air cleanliness in terms of concentration of airborne particles in cleanrooms and clean zones.

The need for a single standard for cleanroom classification and testing was long felt.

Iso 14644 1 2015 specifies the classification of air cleanliness in terms of concentration of airborne particles in cleanrooms and clean zones.

Only particle populations having cumulative distributions based on threshold lower limit particle sizes ranging from 0 1 µm to 5 µm are considered for classification purposes.

The cleanroom class is the level of cleanliness the room complies with according to the quantity and size of particles per volume of air.

The primary authority in the us and canada is the iso classification system iso 14644 1.

To some extent iso 14644 cleanroom standards.

On november 29 2001 the document was canceled and.

Small numbers refer to iso 14644 1 standards which specify the decimal logarithm of the number of particles 0 1 µm or larger permitted per cubic metre of air.

This control is achieved by air pressure and filters.

The latter to cleanrooms where biocontamination may be an issue.

And separative devices as defined in iso 14644 7.

Common applications are medical devices pharmaceutical and semiconductor manufacturing.

After ansi and iest petitioned to iso for new standards the first document of iso 14644 was published in 1999 iso 14644 1.

And separative devices as defined in iso 14644 7.

Only particle populations having cumulative distributions based on threshold lower limit particle sizes ranging from 0 1 µm to 5 µm are considered for classification purposes.

Cleanrooms are used for manufacturing where high levels of cleanliness and sterility are required.

Iso 14644 standards were first formed from the us federal standard 209e airborne particulate cleanliness classes in cleanrooms and clean zones.

A cleanroom is an enclosed room equipped to control the levels of airborne particulate matter.

Iso 14644 1 cleanroom classifications a question commonly asked is what is a clean room generally speaking a clean room is an enclosed room that has equipment which controls the amount of particulate matter in the air by using air pressure and filters.

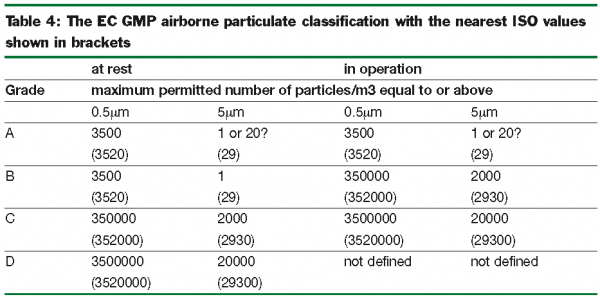

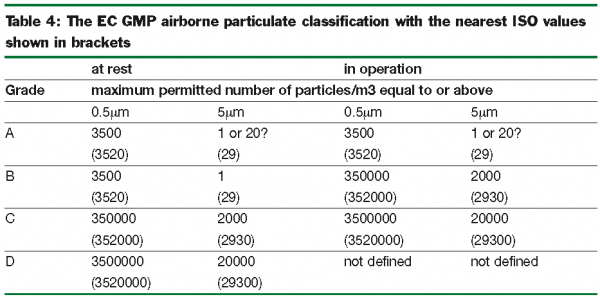

The former applies to clean rooms in general see table below.